Modern automotive diagnostics rely heavily on On-Board Diagnostics (OBD) systems to monitor vehicle performance and identify potential issues. However, accessing the OBD port can sometimes be challenging due to its location or workspace constraints. An OBD extension cable serves as a crucial diagnostic tool that bridges the gap between your diagnostic equipment and the vehicle's OBD port, providing enhanced flexibility and accessibility during troubleshooting procedures. These specialized cables have become indispensable in professional automotive repair environments where efficiency and accuracy are paramount.

Enhanced Accessibility and Workspace Flexibility

Overcoming Physical Constraints in Vehicle Diagnostics

The OBD port location varies significantly across different vehicle models and manufacturers, often positioned in cramped or hard-to-reach areas beneath the dashboard. Professional technicians frequently encounter situations where the standard diagnostic tool cable length proves insufficient for comfortable operation. An OBD extension cable eliminates these physical limitations by providing additional reach and positioning flexibility during diagnostic procedures.

This enhanced accessibility becomes particularly valuable when working on larger vehicles, trucks, or specialized equipment where the operator needs to move freely around the vehicle while maintaining a stable connection to the diagnostic port. The extended cable length allows technicians to position their diagnostic equipment at optimal locations for better visibility and ergonomic comfort during extended troubleshooting sessions.

Improved Ergonomics for Automotive Professionals

Extended diagnostic cables significantly reduce physical strain on automotive professionals by eliminating the need to work in awkward positions or cramped spaces. Technicians can position their diagnostic scanners on nearby workbenches or mobile carts while maintaining a secure connection to the vehicle's OBD system. This improved ergonomic setup reduces fatigue and allows for more accurate diagnostic readings over extended periods.

The flexibility provided by these extension cables also enables multiple technicians to collaborate more effectively on complex diagnostic procedures. Team members can position themselves optimally around the vehicle while sharing access to the same diagnostic data stream, improving overall workshop efficiency and diagnostic accuracy.

Diagnostic Equipment Protection and Longevity

Reducing Wear on Expensive Diagnostic Tools

Professional automotive diagnostic equipment represents a significant investment for repair facilities and independent technicians. The repeated stress of connecting and disconnecting diagnostic tools directly to vehicle OBD ports can cause premature wear on connector pins and housing components. An OBD extension cable acts as a protective barrier, absorbing the mechanical stress of frequent connections while preserving the integrity of expensive diagnostic equipment.

These extension cables typically feature robust construction with reinforced connector housings and strain relief mechanisms that withstand the rigors of daily shop use. By utilizing an extension cable, the wear and tear occurs on the more affordable cable rather than the expensive diagnostic scanner, resulting in significant long-term cost savings for automotive professionals.

Prevention of Accidental Damage During Diagnostics

Working in tight spaces around vehicles increases the risk of accidentally damaging diagnostic equipment or vehicle components during the diagnostic process. Extension cables provide a safety buffer that reduces the likelihood of equipment damage from inadvertent impacts or cable tension. The additional cable length allows diagnostic tools to be positioned away from moving parts, hot engine components, or areas where they might be accidentally knocked or stepped on.

Furthermore, the flexibility provided by extension cables reduces stress on both the vehicle's OBD connector and the diagnostic equipment's cable, minimizing the risk of connector damage that could result in costly repairs or diagnostic accuracy issues. This protection is particularly important when working on newer vehicles with sensitive electronic systems that require precise diagnostic connections.

Operational Efficiency and Productivity Benefits

Streamlined Multi-Vehicle Diagnostic Workflows

High-volume automotive repair facilities often need to perform diagnostics on multiple vehicles simultaneously or in rapid succession. OBD extension cables facilitate more efficient workflow management by allowing diagnostic equipment to remain stationary while technicians move between different vehicles. This setup reduces the time required for equipment setup and breakdown between diagnostic sessions, significantly improving overall shop productivity.

The extended reach capability also enables technicians to perform diagnostics on vehicles parked in less accessible positions within the shop, maximizing the use of available workspace without compromising diagnostic capability. This flexibility becomes particularly valuable during peak business periods when shop space utilization directly impacts revenue generation.

Enhanced Data Collection and Analysis Capabilities

Extended diagnostic cables enable more comprehensive data collection during vehicle testing procedures. Technicians can position diagnostic equipment for optimal visibility while simultaneously operating vehicle controls or observing engine behavior during live data streaming sessions. This enhanced operational flexibility leads to more accurate diagnostic conclusions and reduces the time required to identify complex intermittent problems.

The ability to maintain continuous diagnostic connectivity while moving around the vehicle also facilitates more thorough testing procedures, such as road testing with real-time data monitoring or performing component activation tests while observing system responses from different vantage points around the vehicle.

Technical Specifications and Compatibility Considerations

Multi-Protocol Support and Universal Compatibility

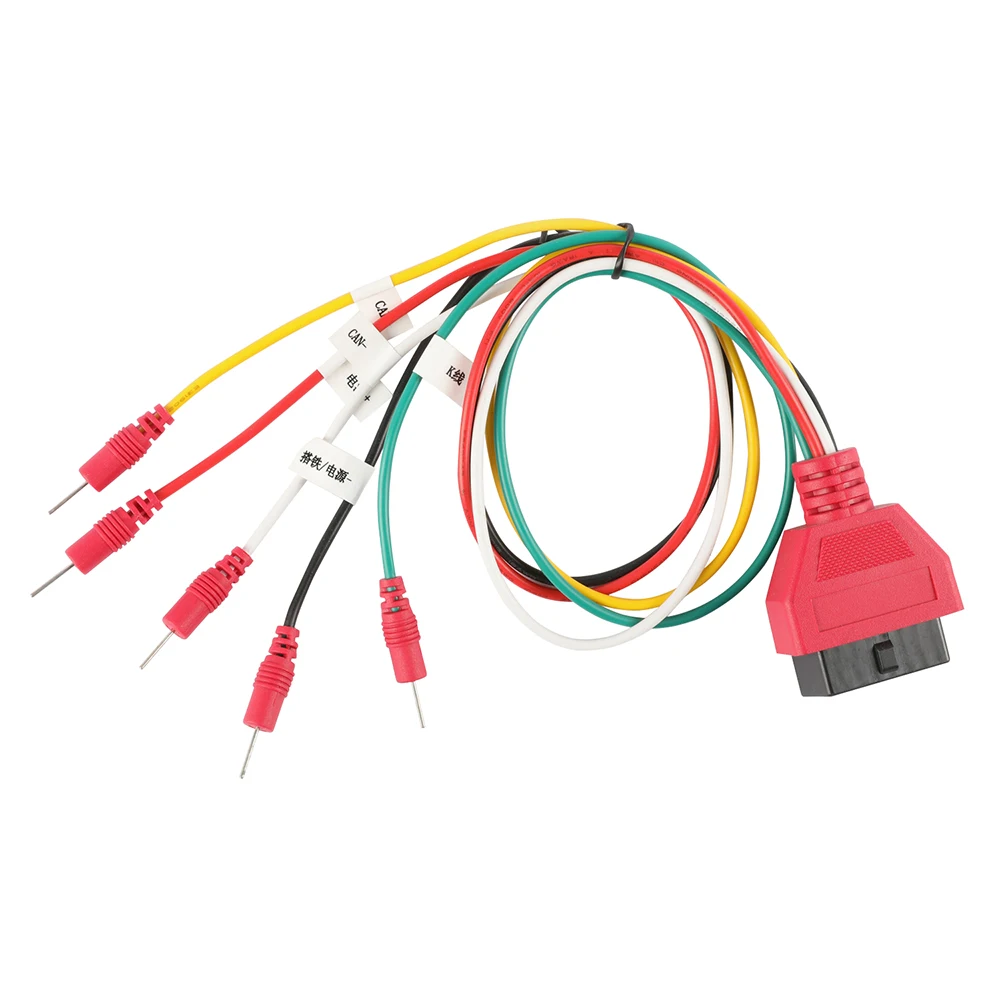

Modern OBD extension cables are designed to support multiple diagnostic protocols including OBD-II, CAN-BUS, ISO 9141, KWP2000, and J1850 standards. This broad compatibility ensures that a single extension cable can be used with diagnostic equipment across different vehicle makes and model years, maximizing the investment value for automotive professionals working on diverse vehicle populations.

The 16-core wire configuration found in professional-grade extension cables ensures complete signal integrity across all OBD communication channels, maintaining diagnostic accuracy regardless of the specific protocol or diagnostic procedure being performed. This comprehensive connectivity eliminates the need for multiple specialized cables while ensuring reliable performance across all supported vehicle types.

Signal Integrity and Electrical Specifications

High-quality OBD extension cables maintain strict electrical specifications to ensure reliable data transmission over extended distances. Proper impedance matching, shielding, and wire gauge selection are critical factors that distinguish professional-grade cables from inferior alternatives. These technical specifications directly impact diagnostic reliability and accuracy, making cable quality a crucial consideration for professional applications.

The electrical characteristics of extension cables must maintain compatibility with both 12V and 24V vehicle electrical systems while providing adequate current carrying capacity for diagnostic equipment power requirements. Professional cables typically incorporate multiple layers of shielding to prevent electromagnetic interference that could compromise diagnostic data integrity in electrically noisy automotive environments.

Cost-Effectiveness and Return on Investment

Reduced Equipment Replacement and Maintenance Costs

The protective benefits provided by OBD extension cables translate directly into reduced equipment maintenance and replacement costs over time. By absorbing the mechanical wear associated with frequent connector engagement, these cables extend the operational life of expensive diagnostic scanners and reduce the frequency of connector repairs or replacements.

Professional automotive diagnostic equipment can cost thousands of dollars, making protection of this investment a priority for repair facilities. Extension cables represent a minimal additional cost that provides substantial long-term financial benefits through equipment protection and extended service life.

Improved Workshop Efficiency and Revenue Generation

The operational efficiencies gained through the use of extension cables directly contribute to improved shop productivity and revenue generation. Reduced setup time between diagnostic procedures, improved technician comfort and accuracy, and enhanced equipment protection all combine to create measurable improvements in workshop performance metrics.

These productivity improvements become particularly significant in high-volume repair environments where small efficiency gains compound into substantial annual cost savings and revenue increases. The relatively modest investment in quality extension cables typically pays for itself within a short period through improved operational efficiency.

FAQ

What length options are available for OBD extension cables

OBD extension cables are commonly available in lengths ranging from 1.5 feet to 16 feet, with 6-foot and 10-foot lengths being the most popular choices for professional applications. The optimal length depends on your specific workspace requirements and the typical positioning of diagnostic equipment relative to vehicle OBD ports. Longer cables provide maximum flexibility but may introduce slight signal delays in some high-speed communication protocols.

Are OBD extension cables compatible with all diagnostic scanners

Most quality OBD extension cables feature standard OBD-II connector configurations that are compatible with the majority of professional diagnostic scanners and code readers. However, some specialized diagnostic equipment may have proprietary connector designs that require specific cable types. Always verify connector compatibility before purchasing an extension cable for use with specific diagnostic equipment.

Can using an extension cable affect diagnostic accuracy or speed

High-quality OBD extension cables with proper electrical specifications should not significantly impact diagnostic accuracy or communication speed when used within their design parameters. However, very long cables or those with poor electrical characteristics may introduce signal degradation that could affect performance. Professional-grade cables with appropriate shielding and wire specifications maintain signal integrity for reliable diagnostic performance.

How do I maintain and care for OBD extension cables

Proper maintenance of OBD extension cables involves regular inspection of connector pins for damage or corrosion, gentle handling to prevent cable stress and kinking, and protection from exposure to automotive fluids or extreme temperatures. Clean connectors periodically with appropriate contact cleaner and store cables in protective cases when not in use to maximize their operational life and maintain diagnostic reliability.