Modern vehicle diagnostics have revolutionized automotive maintenance and repair, making it essential for technicians and car enthusiasts to have reliable access to onboard diagnostic systems. An OBD extension cable serves as a crucial bridge between diagnostic tools and vehicles, particularly when standard connections prove insufficient or impractical. These specialized cables extend the reach of diagnostic equipment, enabling more flexible positioning and improved accessibility during troubleshooting procedures.

The automotive industry has witnessed significant advancements in diagnostic technology, with OBD-II systems becoming standardized across most vehicles manufactured since 1996. However, accessing these diagnostic ports can sometimes present challenges due to their location within the vehicle cabin. Extension cables address these accessibility issues while maintaining signal integrity and diagnostic accuracy.

Professional automotive technicians and DIY mechanics alike benefit from the enhanced flexibility that extension cables provide. These cables eliminate the need to work in cramped positions while maintaining a stable connection to the vehicle's diagnostic system. The result is more efficient diagnostic procedures and reduced physical strain during extended troubleshooting sessions.

Understanding OBD Extension Cable Technology

Cable Construction and Design

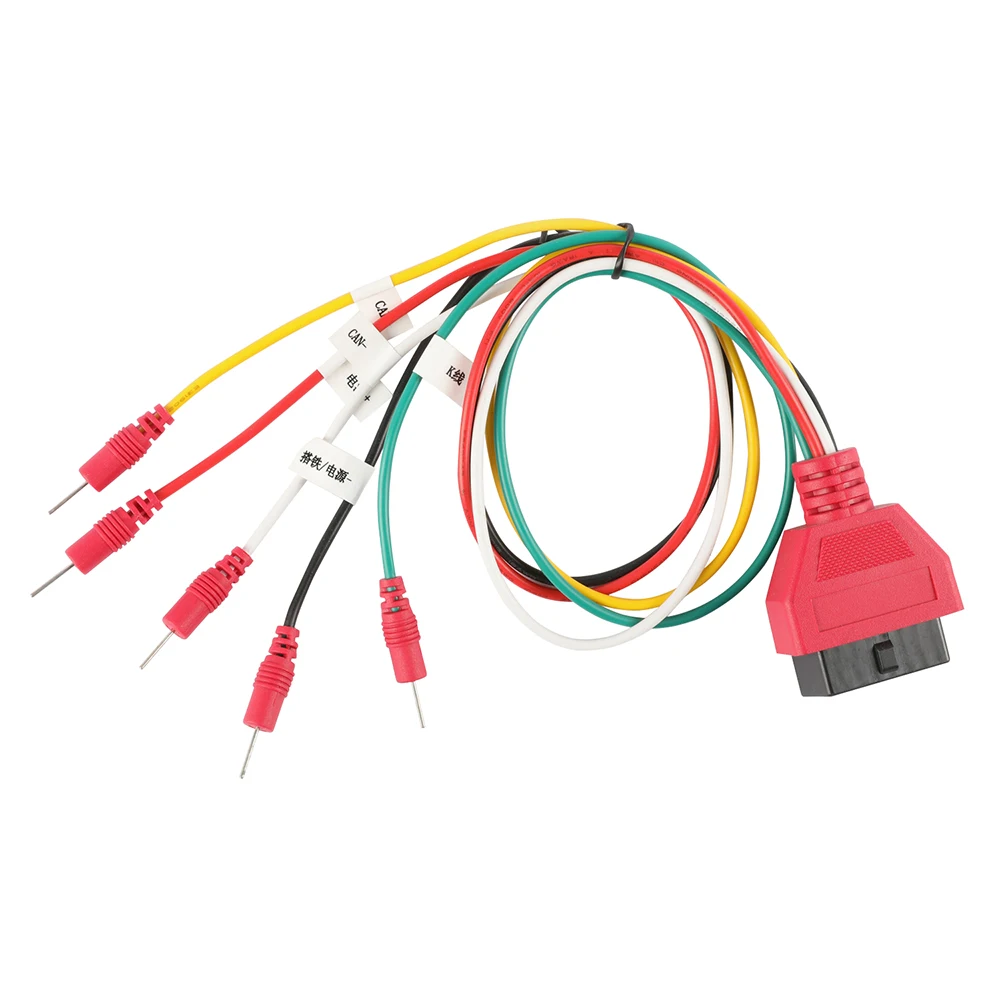

Quality OBD extension cables feature robust construction designed to handle the electrical demands of modern diagnostic systems. The internal wiring typically consists of multiple copper conductors, each carefully shielded to prevent electromagnetic interference. High-grade insulation materials protect these conductors from environmental factors and mechanical stress during regular use.

The connector design plays a critical role in maintaining reliable connections. Male and female OBD-II connectors must provide secure mechanical coupling while ensuring optimal electrical contact across all sixteen pins. Premium extension cables incorporate gold-plated contacts to resist corrosion and maintain long-term conductivity.

Cable length represents another important consideration, with most professional-grade extensions ranging from three to ten feet. Longer cables provide greater flexibility but may introduce slight signal degradation, making it essential to select appropriate lengths based on specific application requirements.

Signal Integrity and Data Transmission

Maintaining signal integrity across the extension cable requires careful attention to impedance matching and noise reduction. Quality cables incorporate twisted-pair construction for differential signals and appropriate shielding to minimize external interference. These design elements ensure that diagnostic data remains accurate and reliable throughout the extended connection.

The OBD-II protocol operates at relatively low speeds compared to modern data networks, typically ranging from 10.4 kbps to 500 kbps depending on the specific protocol in use. This relatively modest bandwidth requirement allows properly designed extension cables to maintain full compatibility with all standard OBD-II communication protocols including ISO 9141-2, KWP2000, and CAN bus systems.

Temperature considerations also affect cable performance, particularly in automotive environments where extreme temperatures are common. Quality extension cables utilize materials rated for automotive temperature ranges, ensuring reliable operation from -40°C to +85°C without signal degradation or mechanical failure.

Practical Applications in Vehicle Diagnostics

Workshop Environment Benefits

Professional automotive repair facilities benefit significantly from OBD extension cable implementation. These cables allow diagnostic equipment to be positioned on workbenches or mobile carts while maintaining connections to vehicles on lifts or in tight service bays. This arrangement improves workspace organization and reduces the risk of equipment damage from accidental impacts.

Extended diagnostic sessions become more comfortable for technicians who no longer need to work in awkward positions beside the vehicle. The ability to position diagnostic tools at ergonomic heights reduces fatigue and improves diagnostic accuracy through better equipment visibility and control.

Multiple technicians can collaborate more effectively when diagnostic equipment can be positioned in accessible locations. Training scenarios particularly benefit from this flexibility, allowing instructors to demonstrate procedures while maintaining clear sight lines for students.

Mobile Diagnostic Applications

Mobile diagnostic services rely heavily on flexible equipment arrangements to accommodate various vehicle types and service locations. Extension cables enable diagnostic equipment to be positioned safely away from traffic areas while maintaining connections to vehicles parked in less-than-ideal locations.

Fleet maintenance operations benefit from the ability to perform diagnostics on vehicles in parking areas without requiring dedicated service bays. Extension cables allow diagnostic equipment to be positioned in weather-protected areas while accessing vehicles exposed to outdoor conditions.

Emergency roadside diagnostics become more practical with extension cables that allow diagnostic equipment to be positioned safely away from traffic while maintaining connections to disabled vehicles. This safety benefit proves particularly valuable for commercial vehicle operations where downtime costs are significant.

Selection Criteria for Professional Use

Quality Standards and Certifications

Professional-grade OBD extension cables should meet or exceed automotive industry standards for electrical performance and environmental resistance. Look for cables that comply with relevant ISO standards and carry appropriate certifications from recognized testing organizations.

Conductor specifications play a crucial role in long-term reliability. Quality cables utilize stranded copper conductors with appropriate gauge ratings to handle the electrical loads imposed by various diagnostic protocols. Solid conductors, while less expensive, prove more susceptible to fatigue failure in mobile applications.

Connector quality significantly impacts overall cable performance and longevity. Premium connectors feature precision-molded housings with secure latching mechanisms and gold-plated contacts for corrosion resistance. Avoid cables with loose-fitting connectors that may cause intermittent connections during diagnostic procedures.

Environmental Considerations

Automotive environments present numerous challenges for electrical equipment, including temperature extremes, moisture exposure, and mechanical stress. Quality extension cables incorporate materials and construction techniques designed to withstand these demanding conditions without compromising electrical performance.

Cable jacket materials should provide resistance to automotive fluids including engine oil, transmission fluid, and various cleaning solvents commonly encountered in repair facilities. Flexible PVC and polyurethane jackets offer good chemical resistance while maintaining flexibility across automotive temperature ranges.

Strain relief design at connector interfaces prevents cable damage from repeated flexing and pulling forces. Quality cables incorporate molded strain reliefs that distribute mechanical stress across larger areas, reducing the likelihood of conductor breakage near connector joints.

Installation and Best Practices

Proper Cable Management

Effective cable management prevents damage and ensures reliable diagnostic connections. Route extension cables away from potential pinch points and avoid sharp bends that could stress internal conductors. Temporary cable routing during diagnostic procedures should consider vehicle movement and technician workspace requirements.

Connector orientation plays a role in maintaining secure connections. Ensure that extension cable connectors align properly with both the vehicle OBD port and diagnostic equipment interfaces. Forced connections can damage connector pins and compromise diagnostic reliability.

Regular inspection of extension cables helps identify potential issues before they affect diagnostic procedures. Check connector pins for corrosion or damage, inspect cable jackets for cuts or abrasions, and verify that latching mechanisms function properly.

Troubleshooting Connection Issues

Connection problems with extension cables typically manifest as intermittent communication errors or complete loss of diagnostic communication. Systematic troubleshooting begins with verification of connections at both ends of the extension cable, ensuring that all connectors seat fully and latch securely.

Environmental factors can affect cable performance, particularly in outdoor or high-moisture conditions. Protect connectors from moisture ingress and allow cables to reach operating temperature before attempting diagnostic communication in extreme temperature conditions.

Cable length limitations may affect some diagnostic applications, particularly those requiring high-speed communication or precise timing. If communication issues persist despite proper connections, consider using a shorter extension cable or repositioning equipment to minimize cable length requirements.

FAQ

What is the maximum recommended length for an OBD extension cable?

Most manufacturers recommend keeping extension cable lengths under 10 feet to maintain signal integrity and prevent communication errors. Longer cables may work in some applications but could introduce timing issues or signal degradation that affects diagnostic reliability. Professional applications typically use cables between 3-6 feet for optimal performance.

Are OBD extension cables compatible with all diagnostic tools?

Quality OBD extension cables maintain full compatibility with all standard OBD-II diagnostic tools and protocols. The cable acts as a transparent extension of the vehicle's diagnostic port, preserving all electrical characteristics necessary for proper communication. However, some proprietary diagnostic interfaces may have specific requirements that should be verified with the equipment manufacturer.

Can extension cables affect diagnostic accuracy or speed?

Properly designed extension cables should not affect diagnostic accuracy when used within their specified length limits. Communication speed may experience slight delays due to increased cable length, but these delays are typically negligible for standard diagnostic procedures. Poor quality cables or excessive lengths may introduce errors that could affect diagnostic results.

How do I maintain an OBD extension cable for long-term reliability?

Regular maintenance includes visual inspection of the cable jacket and connectors, cleaning connector contacts with appropriate solvents, and proper storage to prevent damage. Avoid coiling cables too tightly, protect connectors from contamination, and replace cables showing signs of wear or damage. Store cables in dry conditions away from extreme temperatures when not in use.