The reliability of diagnostic procedures in modern automotive systems heavily depends on the quality of signal transmission between diagnostic tools and vehicle control modules. When technicians need to extend their reach or work in challenging environments, they often turn to specialized connection solutions that maintain signal integrity while providing operational flexibility. Understanding the relationship between cable extensions and signal stability becomes crucial for accurate diagnostics and efficient troubleshooting in professional automotive environments.

Signal degradation represents one of the most significant challenges when extending diagnostic connections beyond their standard reach. The electrical characteristics of extension cables directly impact the quality of data transmission between diagnostic equipment and vehicle systems. Professional technicians must carefully consider these factors to ensure accurate readings and prevent diagnostic errors that could lead to misidentification of vehicle issues.

Signal Transmission Fundamentals in Automotive Diagnostics

Electrical Properties Affecting Data Integrity

The foundation of reliable diagnostic communication lies in understanding how electrical signals behave within extension cables. Resistance, capacitance, and impedance characteristics of the cable materials directly influence signal quality. Higher resistance values can cause voltage drops that affect the amplitude of digital signals, potentially leading to communication errors between diagnostic tools and vehicle control modules.

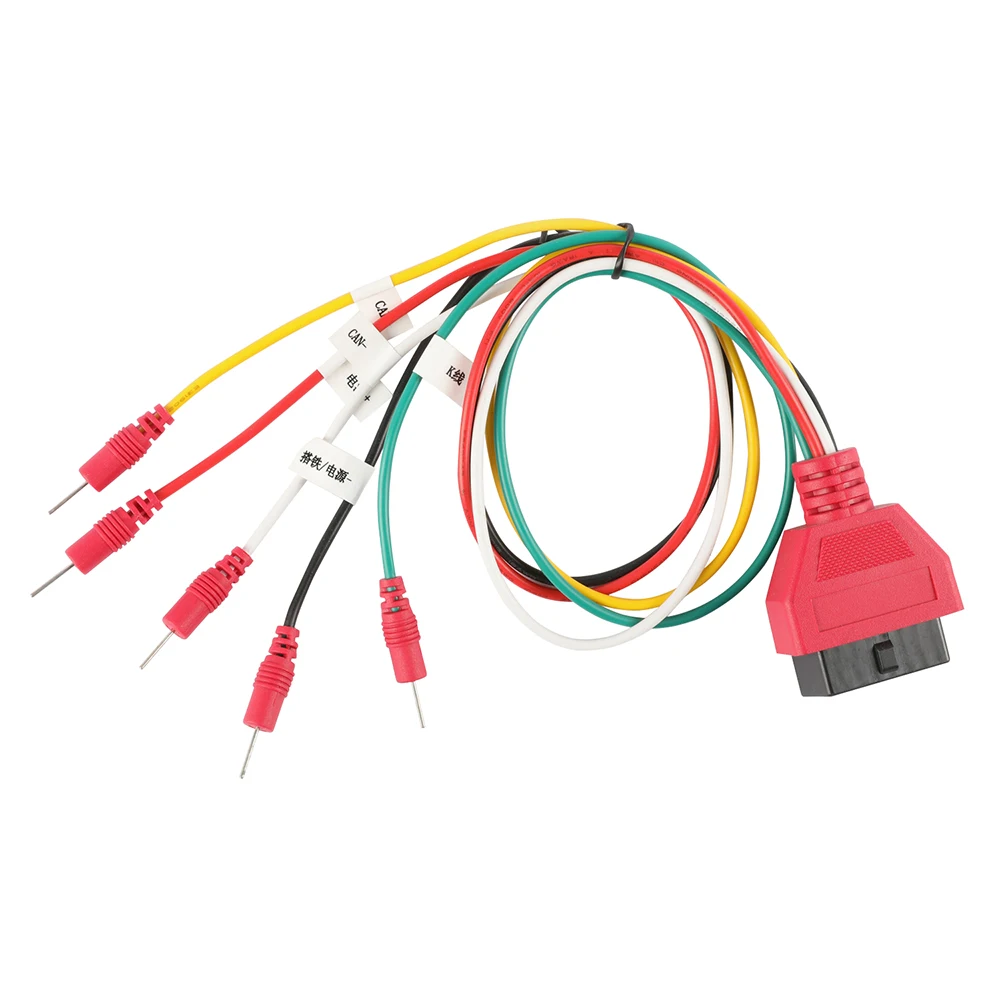

Cable construction plays a vital role in maintaining signal integrity across extended distances. Multi-core designs with proper shielding help minimize electromagnetic interference while preserving the timing characteristics essential for accurate data transmission. The gauge of individual conductors must be appropriate for the current requirements of the diagnostic protocol being used.

Temperature variations can also affect the electrical properties of extension cables, particularly in automotive environments where extreme conditions are common. Quality cables incorporate materials that maintain stable electrical characteristics across wide temperature ranges, ensuring consistent performance regardless of environmental conditions.

Communication Protocol Requirements

Different diagnostic protocols have varying sensitivity to signal degradation caused by cable extensions. CAN bus communications, which form the backbone of modern vehicle diagnostics, require precise timing and voltage levels to maintain reliable data transmission. Even minor signal distortions can cause communication failures or corrupt diagnostic data.

The baud rate of diagnostic communications affects the sensitivity to cable-induced signal degradation. Higher speed communications are more susceptible to timing variations and signal quality issues that may be introduced by extension cables. Understanding these relationships helps technicians select appropriate extension solutions for specific diagnostic applications.

Protocol-specific requirements for termination and impedance matching become critical when using extension cables. Proper impedance matching prevents signal reflections that can cause communication errors and ensure reliable data transmission across extended connection paths.

Cable Design Factors Influencing Performance

Conductor Configuration and Materials

The internal construction of an OBD extension cable significantly impacts its ability to maintain signal stability over extended distances. Stranded copper conductors offer superior flexibility while maintaining excellent conductivity, making them ideal for diagnostic applications where cables may be frequently repositioned or routed through tight spaces.

Wire gauge selection must balance flexibility with electrical performance requirements. Thicker conductors provide lower resistance and better signal transmission characteristics but may sacrifice flexibility and ease of handling. Professional-grade extension cables optimize this balance to deliver reliable performance while maintaining practical usability in workshop environments.

The quality of conductor insulation affects both signal integrity and long-term reliability. High-quality insulation materials provide consistent dielectric properties that help maintain stable capacitance and impedance characteristics throughout the cable length. This stability is essential for preserving the timing accuracy required by modern diagnostic protocols.

Shielding and Noise Reduction

Electromagnetic interference represents a significant challenge in automotive diagnostic environments where multiple electronic systems operate simultaneously. Effective shielding design in extension cables helps protect sensitive diagnostic signals from external interference sources that could corrupt data transmission or cause communication failures.

Braided shielding provides excellent coverage and flexibility, making it well-suited for diagnostic extension cables that require frequent handling and repositioning. The shield coverage percentage directly correlates with the cable's ability to reject electromagnetic interference while maintaining signal integrity across the full frequency spectrum used by diagnostic protocols.

Proper shield termination at both ends of the extension cable ensures effective noise rejection while preventing ground loops that could introduce additional interference. Professional installation techniques and quality connector designs are essential for maintaining the shielding effectiveness throughout the cable assembly.

Length Considerations and Signal Degradation

Distance Limitations in Diagnostic Applications

The maximum practical length for diagnostic extension cables depends on several factors including signal type, communication speed, and cable quality. Standard diagnostic protocols have specific distance limitations that must be respected to maintain reliable communication between diagnostic tools and vehicle systems.

Signal attenuation increases proportionally with cable length, eventually reaching levels where communication becomes unreliable or impossible. Understanding these limitations helps technicians select appropriate cable lengths for specific applications while ensuring adequate signal margins for reliable operation.

Timing delays introduced by longer cables can affect the synchronization of diagnostic communications, particularly in high-speed applications. These delays must be considered when selecting extension cable lengths to ensure compatibility with timing-sensitive diagnostic protocols.

Mitigation Strategies for Long Distance Applications

When longer extension distances are required, signal conditioning techniques can help maintain communication reliability. Active repeaters or signal boosters may be necessary for applications that exceed the practical limits of passive cable extensions while preserving the integrity of diagnostic data.

Cable routing and installation practices can significantly impact signal quality over longer distances. Avoiding parallel runs with power cables and maintaining appropriate separation from potential interference sources helps preserve signal integrity across extended cable lengths.

Quality connectors with gold-plated contacts ensure reliable connections that maintain their electrical characteristics over time. Poor connector quality can introduce resistance and intermittent connections that compromise signal stability regardless of cable quality.

Environmental Factors and Reliability

Temperature Effects on Cable Performance

Automotive diagnostic environments subject cables to wide temperature variations that can affect their electrical and mechanical properties. Quality extension cables incorporate materials and construction techniques that maintain stable performance across the full range of temperatures encountered in automotive applications.

Thermal cycling can cause mechanical stress in cable assemblies, potentially leading to intermittent connections or conductor failures over time. Proper strain relief design and flexible cable construction help minimize these effects and ensure long-term reliability in demanding automotive environments.

Temperature-induced changes in cable capacitance and resistance can affect signal timing and amplitude, particularly in sensitive diagnostic applications. Understanding these effects helps technicians anticipate potential issues and select cables with appropriate temperature compensation characteristics.

Chemical Resistance and Durability

Automotive environments expose cables to various chemicals including fuel, oil, coolants, and cleaning solvents that can degrade cable materials over time. Professional-grade extension cables incorporate chemical-resistant jacket materials that maintain their protective properties despite exposure to these harsh substances.

UV resistance becomes important for cables that may be exposed to sunlight during outdoor diagnostic procedures. Quality cable jackets include UV stabilizers that prevent degradation and maintain flexibility even after extended exposure to solar radiation.

Abrasion resistance ensures that cables maintain their integrity even when subjected to the mechanical wear common in automotive service environments. Reinforced jacket designs and appropriate cable routing help minimize mechanical damage that could compromise signal transmission or create safety hazards.

Testing and Validation Methods

Signal Quality Assessment Techniques

Comprehensive testing of extension cable performance requires specialized equipment capable of measuring signal integrity parameters across the full frequency range used by diagnostic protocols. Oscilloscope measurements can reveal signal distortion, timing variations, and noise levels that might affect diagnostic reliability.

Bit error rate testing provides quantitative assessment of communication reliability over extended cable connections. This testing simulates real-world diagnostic communications while measuring the frequency of transmission errors that could affect diagnostic accuracy.

Time domain reflectometry can identify impedance discontinuities and other cable defects that might not be apparent during normal operation but could cause intermittent communication problems under certain conditions.

Real-World Performance Validation

Laboratory testing must be supplemented with real-world validation using actual diagnostic equipment and vehicles to ensure that extension cables perform reliably in practical applications. This validation should include testing across various vehicle makes and models to ensure broad compatibility.

Long-term reliability testing involves subjecting cables to accelerated aging conditions that simulate years of use in automotive environments. This testing helps identify potential failure modes and ensures that cables maintain their performance characteristics throughout their expected service life.

Compatibility testing with different diagnostic tool brands and models ensures that extension cables work reliably across the full range of equipment commonly used in automotive service facilities.

FAQ

What is the maximum recommended length for an OBD extension cable

The maximum recommended length for OBD extension cables typically ranges from 3 to 6 feet for most diagnostic applications. Beyond this length, signal degradation may begin to affect communication reliability. However, high-quality cables with proper shielding and appropriate conductor gauges can sometimes extend this range while maintaining acceptable performance levels.

How does cable quality affect diagnostic accuracy

Cable quality directly impacts diagnostic accuracy through its effect on signal integrity. Poor quality cables can introduce noise, signal distortion, and timing variations that may cause communication errors or corrupt diagnostic data. This can lead to misdiagnosis, missed fault codes, or intermittent diagnostic tool performance that compromises the reliability of vehicle troubleshooting procedures.

Can using an extension cable cause damage to diagnostic equipment

When properly designed and used within their specifications, quality extension cables should not cause damage to diagnostic equipment. However, cables with poor shielding or inappropriate electrical characteristics might expose diagnostic tools to electrical noise or voltage irregularities that could potentially affect their operation or longevity. Always use extension cables specifically designed for diagnostic applications.

What should I look for when selecting an OBD extension cable

When selecting an OBD extension cable, prioritize proper conductor gauge for signal integrity, comprehensive shielding for noise rejection, and quality connectors with gold-plated contacts for reliable connections. Ensure the cable is designed specifically for diagnostic applications and meets the electrical requirements of your diagnostic equipment. Consider the environmental conditions where the cable will be used and select appropriate jacket materials for chemical and temperature resistance.