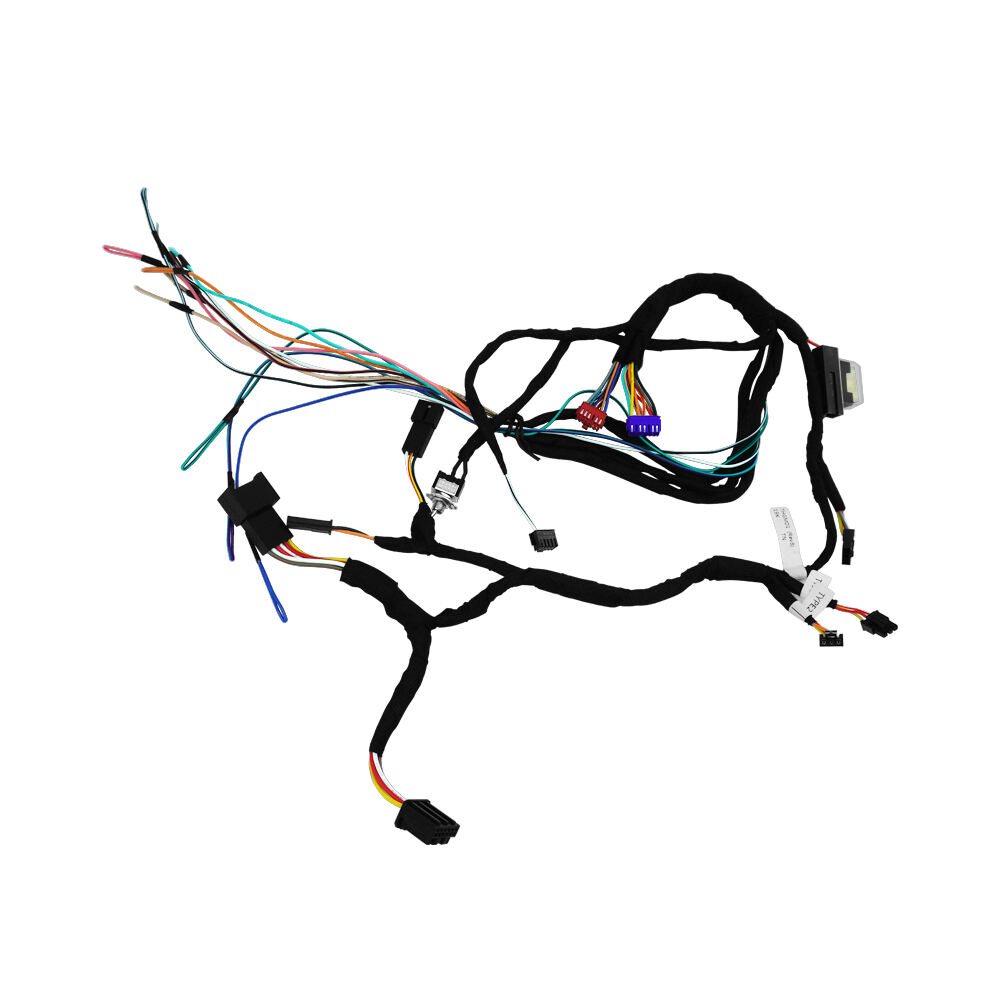

vehicle wiring harness

A vehicle wiring harness serves as the central nervous system of modern automobiles, integrating and organizing the complex network of electrical connections essential for vehicle operation. This sophisticated assembly consists of wires, terminals, connectors, and protective components that safely route electrical power and signals throughout the vehicle. The primary function of a wiring harness is to streamline the electrical system by bundling numerous wires into organized, easy-to-install assemblies. Modern vehicle wiring harnesses are engineered to withstand harsh automotive environments, featuring robust insulation materials and protective coverings that resist heat, moisture, and physical stress. These harnesses support critical vehicle functions including engine management, lighting systems, entertainment systems, and advanced driver assistance features. The design incorporates various safety features such as circuit protection devices and specialized connectors that prevent incorrect installation. Advanced manufacturing techniques ensure consistent quality and reliability, while modular designs facilitate easier maintenance and repairs. The wiring harness has evolved to accommodate the increasing electrical demands of contemporary vehicles, supporting everything from basic operations to sophisticated electronic systems.