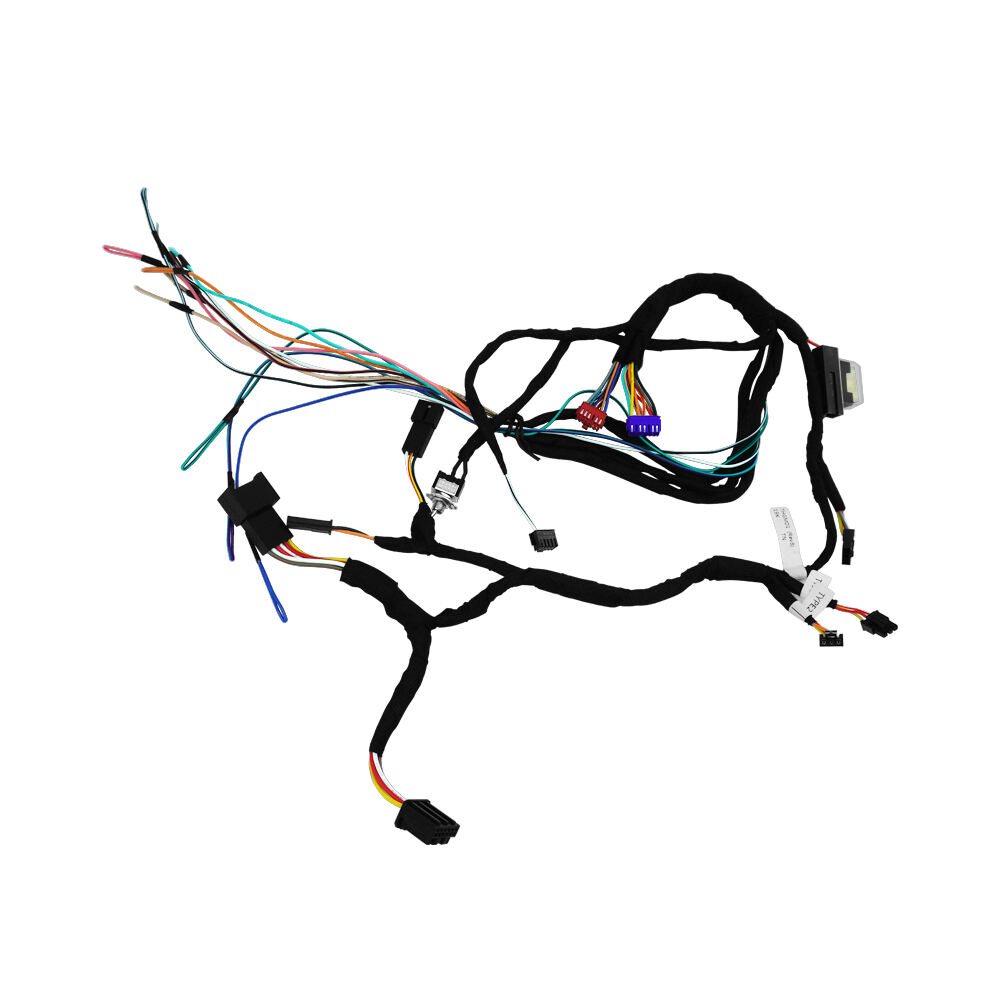

cable harness manufacturer

A cable harness manufacturer specializes in designing and producing custom wiring solutions that streamline electrical connections in various applications. These specialized facilities combine cutting-edge automation technology with precise manual assembly processes to create high-quality wiring assemblies that meet specific industry standards. The manufacturing process involves careful selection of materials, including wires, connectors, and insulation, ensuring optimal performance and durability. Modern cable harness manufacturers employ advanced testing equipment to verify electrical continuity, insulation resistance, and overall functionality of each assembly. They serve diverse industries, including automotive, aerospace, medical equipment, and industrial machinery, providing solutions that range from simple two-wire configurations to complex multi-branch systems. The manufacturing facility typically features climate-controlled production areas, automated wire cutting and crimping machines, and sophisticated quality control systems. These manufacturers maintain strict adherence to international safety standards and regulations, implementing rigorous quality management systems to ensure consistent product excellence. Their capabilities often extend to product design assistance, prototyping, and full-scale production, offering customers comprehensive support throughout the entire development process.