Înțelegere Harnes pentru camioane grele Principii de bază

Ce este o Harnes pentru camioane grele ?

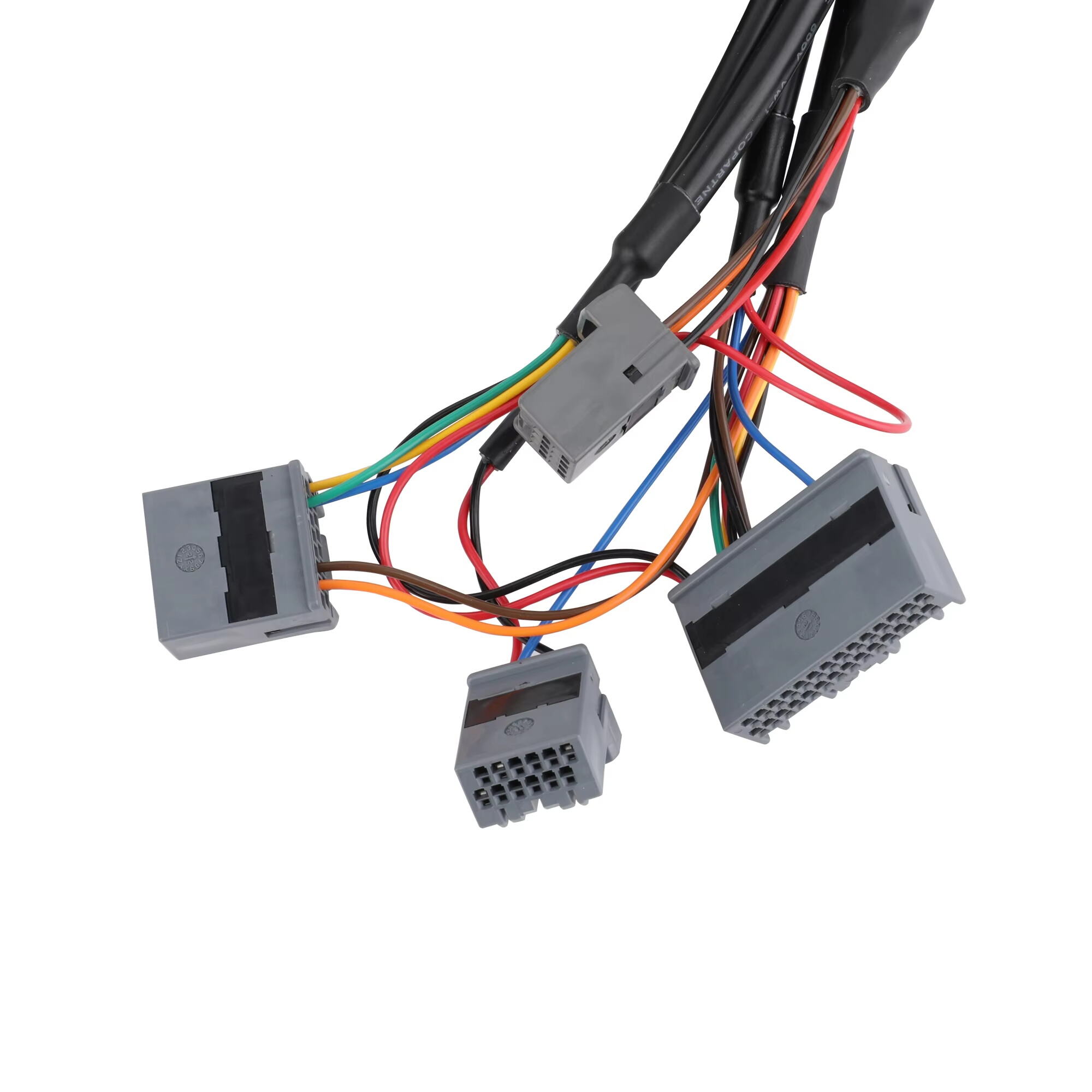

Harnes-ul unui camion greu este o structură de cabluri electrice care transferă semnale către și de la părți ale mașinii, care au nevoie de energie electrică pentru a funcționa corespunzător. În general, acesta include conectoare, terminale și conductoare pentru a interconecta diferitele sisteme electrice ale camionului. Aceste componente creează un sistem organizat care va funcționa cu fiabilitate și fără probleme. Harnes-ul are o funcție importantă, deoarece leagă diferitele sisteme ale camionului: iluminat, motor și sisteme de diagnoză, menținându-le în funcție într-un mod perfect. Aceste harnes-uri pot fi dificile de înțeles corect și sunt foarte importante pentru oricine este responsabil cu întreținerea sau fabricarea camionelor, din cauza efectului pe care l-au asupra sistemului electric general al vehiculului.

De ce este importantă selecția corectă a harnes-ului

Este esențial să se aleagă harnes-ul corespunzător pentru camioane grele, pentru a garanta eficiența maximă a vehiculului și siguranța acestuia. Alegerea unui harnes incorect poate crește dramatic probabilitatea eșecurilor sistemelor electrice și a unei întreruperi costisitoare a funcționării. De fapt, statisticile recente indică o creștere semnificativă a reparațiilor la vehicule din cauza instalărilor defectuoase ale harnes-urilor. Calitatea și structura harnes-ului trebuie să respecte anumite cerințe pentru a preveni astfel de defecțiuni electrice. Selectarea de proiectări și materiale de înaltă calitate în conceperea harnes-ului ajută la eliminarea potențialelor probleme electrice și la asigurarea unei operațiuni sigure și durabile a vehiculului. Este recomandabil să se acorde atenție acestei aspecte celor care doresc să obțină cea mai mare fiabilitate posibilă a timpului de funcționare al vehiculului.

Aplicații comune în mediile heavy-duty

Camioanele grele și arcurile sunt utilizate în multe industrii, cum ar fi construcții, minerit și transport. Acestea joacă un rol important în îmbunătățirea performanței camioanelor de dezăvăruire, gruarelor și vehiculelor de transport de marfă care funcționează în condiții dificile. În aceste medii de lucru extrem de stresante, arcurile permit schimbul ușor de informații și colaborarea fără probleme a diferitelor sisteme, creșterea productivității și a sinergiilor operaționale. Folosirea lor tactică înseamnă mai puțin timp de oprire pentru întreținere și finalizarea mai rapidă a lucrărilor, transformându-le astfel într-o necesitate într-un mediu care cere performanță ridicată și fiabilitate. Aceste aplicații pot ajuta profesioniștii să aleagă produsele de arc potrivite pentru cerințele specifice ale industriei lor.

Tipuri de harnasuri pentru camioane grele

Direct-Fit vs. Arcuri Universale

Când cumpărați harnesuri de cablare pentru camioane grele, este o idee bună să examinați harnesurile cu ajustare directă și cele universale. Aceste harnesuri sunt complet compatibile cu cele montate de fabrică pentru motor, lumini frontale și harnesul corporal din spate, instalate pe vehiculul Original Truck. Pe de altă parte, harnesurile universale sunt adaptables pentru a se potrivi cu majoritatea camioanelor, făcându-le potrivite pentru multe aplicații, dar pot să necesite unele modificări pentru montare. Deși harnesurile cu ajustare directă sunt de obicei mai convenabile din punct de vedere al facilității de montare, harnesurile universale oferă mai multe opțiuni.

Opțiuni Pro-Series și Personalizabile

Pentru cei cu nevoi de performanță ridicate, arcurile din seria Pro sunt cele potrivite. Aceste strijeli sunt realizate cu atenție la detaliu, se montează rapid și oferă performanță la cel mai înalt standard, în special pe terenuri accidentate. Personalizare Pe de altă parte, personalizarea oferă soluții concepute expres pentru anumite modele de camioane grele. Utilizarea arcurilor personalizate oferă avantaje importante, deoarece îmbunătățește funcționarea vehiculului prin integrarea unor caracteristici avansate adaptate unei aplicații specifice. Clienții care folosesc aceste setări specifice au constatat o diferență, din punct de vedere al performanței, în ceea ce privește eficiența și siguranța.

Arcuri specializate pentru condiții extreme

Când lucrăm în medii extrem de aspre, cum ar fi căldura extremă sau frigul intens sau un mediu cu vibrații puternice, harnesul special devine foarte important. Acestea sunt fabricate din cele mai bune materiale, pot face față condițiilor de lucru grele și uneori folosesc tehnologii de ultimă generație pentru a funcționa chiar mai bine. De exemplu, izolația din siliconă rezistentă la temperaturi ridicate asigură o performanță continuă la temperaturi mari. În aplicații atât de rude ca construcții sau minerit, care necesită cât mai multă soliditate posibilă, utilizarea de harnesuri specializate poate face o diferență semnificativă în ceea ce privește eficiența și siguranța. Alegerea unui harnes corect proiectat pentru mediile aspre poate contribui la reducerea riscurilor și susținerea operațiunilor grele cu flux liber.

Factori Cheie pentru Alegerea Harnesului Potrivit

Evaluarea Condițiilor Medaluare (Căldură, Vibrație, Umiditate)

Alegerea unui harnes adecvat pentru camioane grele începe cu identificarea factorilor ambientali, cum ar fi căldura, vibrația și umiditatea. Aceștia reprezintă cu mult cei mai importanți factori în ceea ce privește performanța și durata de viață a oricărui harnes. De exemplu: deterioarea izolației cauzată de temperaturi ridicate, conectoarele strângute din cauza vibrațiilor în timpul utilizării. Un studiu de caz din aplicațiile industriale a indicat că luarea în considerare a acestor condiții este crucială pentru a evita eșecurile premature ale harnes-ului. Alegerea harnes-urilor care să reziste acestor stresuri diferite ale mediului este prin urmare importantă atunci când se ia în considerare performanța și fiabilitatea pe termen lung pentru camioane grele.

Cereri privind Încărcarea Electrică și Compatibilitatea

Cunoașterea capacității electrice a cablajului unui camion greu este esențială pentru a alege receptacolul potrivit. Există sarcini pentru care fiecare harnes este destinate care ar trebui să fie utilizate; alegerea unei incompatibile ar putea provoca eșecuri ale sistemului și neeficiențe sociale. Compatibilitatea cu alte sisteme electronice din camion este de asemenea un factor esențial. Sunt folosite dimensiuni de cablu corecte și conectoare de tip original pentru o integrare fără probleme în întreaga sistem electrică a camionului. Alegeri inteligente privind aceste elemente elimină problemele potențiale legate de alimentarea electrică și îmbunătățesc performanța acestuia ca camion.

Considerente despre durabilitate și longevitate

Armaturile pentru camioane grele trebuie să fie extrem de rezistente pentru a suporta utilizarea zilnică. Alegerea asamblajelor de armaturi fabricate din materiale durabile poate crește semnificativ viața utilă a asamblajului. Măsuri suplimentare de protecție, cum ar fi întărcerea izolării și aplicarea de acoperiri, pot prelungi durata de viață a unei armate, chiar dacă aceasta este pusă la încercare. Integritatea armaturilor este susținută de o instalare corectă și de menținerea continuă. (Broșura care acoperă utilizarea '... și Armaturi(+)' este disponibilă de asemenea) Conform celor mai bune practici din industrie, materialele de cea mai bună calitate ar trebui selectate pentru a garanta un serviciu de încredere și durabil al armaturilor.

Considerații privind materialele și designul

Alegerea Materialelor Conductor (Cupru, Aluminiu)

Alegerea conductorului. Cele două conductoare care trebuie luate în considerare pentru aplicațiile de arnșaj ale camioanelor grele sunt cupru și aluminiu, fiecare dintre ele oferind proprietăți unice. Cuprul este cunoscut pentru conectivitatea sa excelentă, care permite transmiterea unei puteri mari în aplicații în care se cere eficiență. Dar cuprul este mai greu și mai scump decât aluminiu. Sau, o variantă mai ieftină este aluminiu, dar acesta este mai puțin conductiv și mai greu. Decizia între cele două implică luarea în considerare a amprentei ecologice respective și a stării reciclării. Standardurile din industrie v-au putea ajuta să selectați materialul de conductor potrivit care să îndeplinească toate cerințele de performanță și durabilitate.

Tipuri de izolare pentru protecție și siguranță

Tipul de izolare corespunzător este crucial pentru siguranța și longevitatea fasciculelor de camioane grele. Materialul izolant are abilități protective diferite, PVC-ul fiind cel mai ieftin, dar nu funcționează la temperaturi ridicate. Materiale mai robuste, cum ar fi Teflonul și siliconul, oferă o rezistență mai bună la căldură și o flexibilitate crescută la temperaturi extreme. Izolarea elimină scurt-circuiturile electrice și asigură că fascicula este sigură de utilizat, protejând cablurile de avarii și pericolele mediului. Cu atât mai multe factori mediici, cu atât este mai important să se aleagă cea mai bună izolare pentru a face față condițiilor în care va fi operat camionul.

Protecție împotriva EMI și coroziunea

Sistemul de cablare a camioanelor este cel mai potrivit să fie protejat pentru a se preveni EMI-ul și coroziunea, care pot afecta semnificativ performanța. EMI-ul poate interfera cu propagarea semnalului, provocând ineficiențe în sistemele electronice. Protecția pentru a minimiza impactul acestei interferențe implică anumite materiale și metode de protecție redirectate de industrie. Împachetarea cablajelor cu scuturi metalice și aplicarea unor revărsuri specifice EMI sunt două abordări comune. De asemenea, conservarea împotriva coroziunii prin revărsuri protecționează contribuie la o viață utilă prelungită a cablajelor. Studiile de caz subliniază frecvent consecințele costisitoare ale unei protecții inadecvate și întăresc argumentul pentru măsuri de protecție, menite să țină echipamentele productive în teren.

Practici de Instalare și Menținere Optimale

Ghid de Instalare Paș cu Paș

Este important să instalați corect harnes-urile pentru camioane grele, astfel încât acesta să poată fi folosit cu cea mai bună performanță și durabilitate. Mai jos se găsește un ghid care vă va ajuta în timpul instalării. Totul începe cu colectarea unor unelte de bază, cum ar fi tăietoare de fir, unelte de presare și șurubelioare cu moment. Citiți cu atenție manualul fabricantului pentru a evita erorile comune, cum ar fi conexiuni greșite sau lipsa deconectării la masă. Pentru o referință ușoară în timpul vizitelor la clienți, instrucțiunile detaliate, împreună cu materialele de sprijin, precum foile de specificații și videoclipurile „cum să” sunt instrumente cruciale pentru installeri.

Fixarea harnes-ului pentru rezistență la vibrații

În camioane mari, este important ca harnurile să fie bine imobilizate împotriva vibrațiilor pentru a preveni eventualele daune. Asigurarea rezistenței la vibrații necesită în mod de bază o serie de măsuri preventive, inclusiv suporturi amortizoare vibrații și conducte flexibile. În general, standardele industriale promovează plasarea fermelor sau punctelor de siguranță care sunt poziționate pentru un mișcare minim. Adoptarea acestor criterii poate reduce semnificativ potențialul uzurii și eșecului cauzat de vibrații continue.

Sfaturi pentru inspectare rutinieră și depanare

Inspectarea frecventă este cheia pentru a vă asigura că harnesul continuă să funcționeze corect. Examinați la intervale regulate prin intermediul kilometrajului 5 - intensitatea utilizării 6) pentru zone critice; zone legate de articulații și zone legate de mișcarea articulațiilor. Cautați semne de uzurare sau eșec, menținându-va un ochi deschis pentru cabluri stricate sau decolorate în timpul inspecțiilor. Diagnosticele tipice se fac testând continuitatea cu un multimetru și inspectând vizual problemele harnesului. Utilizând inspecții precise și clare împreună cu o abordare sistematică de depanare, veți trebui să faceți față problemelor legate de harnesurile camionelor grele mai puțin adesea.

Conformitate cu standardele industriei

Înțelegerea certificărilor OSHA și ISO

Conformitatea cu OSHA și ISO este esențială pentru siguranța și legalitatea fabricației arnșurilor pentru camioane grele. În timp ce OSHA se concentrează pe reguli referitoare la siguranța locului de muncă, și asigură că zonele de producție respectă standardele care garantează siguranța muncitorilor. Pe de altă parte, ISO oferă numeroase standarde internaționale, cum ar fi ISO 9001 pentru managementul calității, care sunt o condiție prealabilă pentru fabricarea de încredere a arnșurilor pentru camioane grele. Puteți fi pedepsiți, trimiși în judecată sau chiar să vă stricați reputația brandului datorită neconformității. Continuați să aplicați mai multe standarde militare de apărare, aceeași abordare fiind mai importantă și pentru producătorii de semiconductori, astfel încât este recomandabil să vă bazați pe siguranța producției și reținerea celor mai bune practici, etc.

Îndeplinirea specificațiilor automotive și militare

Armele pentru camioane grele trebuie să respecte standarde foarte riguroase din industria automotive și militară pentru a satisface cerințele industriilor specializate. Specificațiile automobilelor tinde să acopere aspecte precum rezistența la căldură și rezistența la vibrații pentru a supraviețui în mediul inimical al vehiculelor. Specificațiile militare sunt chiar mai stricte în ceea ce privește robustețea și fiabilitatea în toate tipurile de condiții. O analiză mai atentă a exemplelor practice ilustrează dificultățile și realizările legate de îndeplinirea acestor cereri exige, cu un accent puternic pe aplicații care nu admit eșecuri când vine vorba de performanță și siguranță. Respectarea acestor standarde asigură nu doar integritatea produsului, dar demonstrează și angajamentul producătorilor față de calitate și funcționarea continuă în diverse situații.

Importanța conformității cu RoHS/REACH

Companiile de producție a arnășugurilor pentru camioane grele au nevoie să respecte normele RoHS și REACH, ceea ce este esențial atât din punct de vedere al responsabilității ecologice, cât și pentru a stabili legitimitatea unei companii pe piață. Deși RoHS limitează substanțele periculoase în dispozitive electrice, REACH se referă la înregistrarea și manipularea sigură a substanțelor chimice. Necomplierea acestor instrucțiuni poate duce la sancțiuni, contaminare pe piață sau proceduri judiciare pentru daune ecologice. Prin aplicarea legii, producătorii beneficiază de creșterea incențivelor consumatorilor și de acces la piețe care au sustenabilitatea ca prioritate. Mai mult, utilizatorii finali apreciază produsele care sunt "sigure" sau "verzi", preferând companiile care respectă aceste reglementări importante.

Întrebări frecvente

Care este scopul unei arnășuguri pentru camioane grele?

Un harnes pentru camion greu este crucial pentru facilitarea unei transmisii eficiente de semnale și a distribuției de energie în sistemele electrice ale camionului, conectând diferite componente precum iluminat și motoare pentru a asigura menținerea operațiunilor complexe fără probleme.

De ce este importantă selecția corectă a unui harnes pentru camion?

Selecția adecvată a harnes-ului este importantă pentru a evita eșecuri electrice, care pot duce la stricări costisitoare. Alegerea harnes-ului potrivit asigură performanța vehiculului, siguranța și durabilitatea, respectând standardele de calitate pentru a preveni probleme electrice.

Ce factori ar trebui să iau în considerare când aleg un harnes pentru camion greu?

Factori cheie includ condițiile climatice, sarcina electrică, cerințele de compatibilitate, durabilitatea și specificațiile specifice industriei. Aceste considerente ajută să se asigure că harnes-ul selectat îndeplinește cerințele operaționale eficient.

Cum diferă harnes-urile direct-fit și universale?

Harnes-urile de montare directă sunt aliniate cu anumite modele de camioane pentru o instalare ușoară, în timp ce harnes-urile universale oferă adaptabilitate între modele, dar pot să necesite personalizare, oferind o flexibilitate mai mare în aplicații diverse.