הבנת תפקיד מערכות החיווט

רכב אמין תלוי במערכות שאינן נראות לעין אך עליהן אנו סומכים תמיד. ליבה של מערכות אלו ברכב מסחרי הוא חגורת משאית כבדה , רשת מורכבת של חוטים, מקלטים ועטיפות הגנה המובילה חשמל ואותות בין מנועים, חיישנים, תאורה, מערכות בלמים ואלקטרוניקה של הקבינה. איךarness מותאם נכון חגורת משאית כבדה מתורגם לביצועים שוטפים וזמינות צי? על ידי ארגון והגנה על מסילות חשמל קריטיות, הארנזה שומרת על תקשורת ברורה, מפחיתה התנגדות חשמלית, ומונעת כשלים שעלולים לעצור את הפעילות.

ה חגורת משאית כבדה מבצעת יותר מרק התחברות בין נקודה A לנקודה B. היא סטנדרטית את ת layouts החשמל לצורך קלות באיתור תקלות, שיפור עקביות ההתקנה ופחת טעויות בהרכבה או תיקון. החל מהמודולים לשליטה במנוע וכלה במעגלים לתאורת המ trailer, חבילת חיווט מותאמת תעזור להבטיח שכל תת-מערכת מקבלת את המתח והסינכרון הנכונים, תוך שמירה על יעילות המנוע ועל ביטחון התפעול.

רכיבים מרכזיים ומבנה

חוטים, בידוד, ואפשרויות מוליך

Arness למשאיות כבדות מורכב מ מוליכים שנבחרו בעבור נ carrying ו גמישות, ומבודדים בחומרים שנבחרו בעבור התנגדות לחום ו הגנה מפני שחיקה. נחושת נשארת המוליך הנפוץ בעבור מוליכות החשמל שלה, אך יש חשיבות לגיוון בקוטר הגימורי ולחומרי הגנה. בידוד בטמפרטורות גבוהות, TPU או פוליאולفين מקושר וקוטר גמישים י aid בשמירה על חיי שירות ארוכים בסביבות קשות.

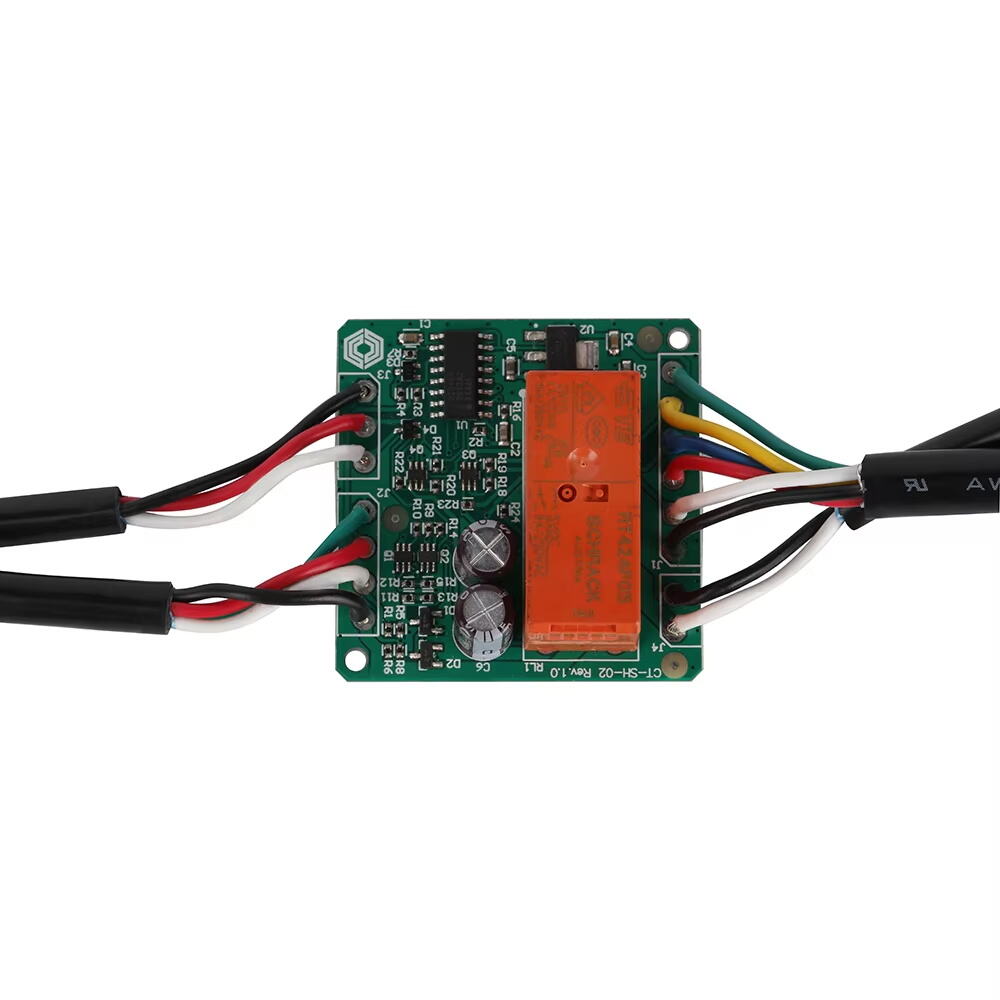

מחברים, חותמים ועטיפות הגנה

מחברים וצמתים חתומים הם רכיבים קריטיים בarness למשאיות כבדות. מחברים מומתים, סדקים וחיבורי צומת יציבים מונעים את חדירת לחות ו אבקה שגורמים לקצרים. שריון, עטיפה תפורה וצינורות התכווצות חום מספקים הגנה מכאנית. כל הרכיבים יחד שומרים על חיבורים יציבים בדרכים קשות ובמגעי קיצוניים, ומשמרים את שלמות האות לאורך אלפי מיילים.

השפעת הarness על הביצועים

дост entregue של כוח ויעילות חשמלית

מה קורה כאשר מתח החשמל יורד או החיבורים הופכים להיות בעלי התנגדות? חבילת חיווט לא מספקת במונית כבדה עשויה לגרום לביצועים נמוכים בזריקת הדלק, משוב אינטרמיטנטי של חיישנים או תאורה חלש — כל אלה משפיעים על הבטחה ועל היעילות. ת_ROUTING_ נכון של החיווט ובחר קוטר מוליך מתאים מקטין ירידה של מתח ומבטיח שהרכיבים מקבלים питון יציב גם תחת עומס, ותומך בעבודת דלק עקבית ובטיפוח פליטה.

שלמות האותות והבקרים האלקטרוניים

מוניות כבדות מודרניות סומכות על מספר הולך וגדל של מערכות בקרה אלקטרוניות. חבילת החיווט במונית הכבדה מובילה אותות חיישנים, פקודות מערכות בקרה, אותות אבחון ומסרי CAN BUS בין המודולים. כאשר החיווט properly shielded ו_ROUTING_ נכון, נמנעת הפרעה ויחס השגיאות יורד, ומאפשר למערכות הבקרה לפעול בדיוק. זה אומר תגובה חלקה של המנוע, נתוני אבחון מדויקים ות integration טובה יותר של תכונות סיוע לנהיגה מתקדמת.

שיקולי עיצוב למשך חיים

עמידות בפני ויברציה ומעגלי טמפרטורה

משאיות פועלות בסביבות שדורשות עמידות. הארנס של משאית כבדה חייב לסבול רטט מתמשך והחלפות טמפרטורה משמעותיות מבלי לגרום לחיכוך או עייפות חיבורים. מעוצבי הארנס משתמשים במתנעים גמישים, תכונות הפחתת מתח ונתיבי כביסה אנטי-רטט כדי להאריך את תקופות השירות ולמנוע מחדלים שיגרמו לעצירה לא מתוכננת.

הגנה against corrosion וח sealing סביבתי

מלח, כימיקלים על הכביש והumidity מהווים אתגרים מתמידים. קורוזיה של פינים וחוטי הכבשה יכולה להוביל לפסיקה או עלייה בהתנגדות. חיבורים חסומים, ציפויים עמידים בפני קורוזיה וכפפות הגנה הן פתרונות נפוצים באריסים של משאיות כבדות כדי להפחית את הסיכון לתקלות שמקורן ברטטב, ולשמור על אמינות לאורך זמן ועל תחזוקה מתוכננת.

התקנה, תיקון ו אבחון

שיטות מומלצות להתקנה

התקנה נכונה של הארנס של משאית כבדה היא חיונית. מיקוד בדרכים מאובטחות, הרחק מחלקי הפליטה החמים וקצות חדים ממזער נזקים. איסוף החוטים וסימוןם תורמים לשירות מהיר ומדויק יותר בעתיד. טכנאי שמבצעים התקנה על פי נסבים סטנדרטיים ומומלצים של חיבורים חשמליים מפחיתים את כמות הפגמים בתיקונים ואת תקלות החשמל שנובעות מהן.

שיטות אבחון וTroubleshooting

כאשר מתרחשת תקלה, תרשים ברור של הארנס מקצר את זמן האבחון. הארנס של המשאית הכבדה תומך בנקודות גישה לאבחון ובפינים לבדיקה שמאפשרים לטכנאי לאתר את הבעיות מבלי לבצע בדיקה הרסנית. שימוש בארנס שתוכנן תוך כדי חשיבה לאבחון מפחית את זמן השבת של המשאית ואת עלות התפעול על ידי ניתוח שורש התקלה במהירות ותיקונים ממוקדים.

התאמהומציה ותאמה

מפרט היצרן (OEM) מול פתרונות שוק שני

מפעילי צוותים ניצבים לרוב בפני בחירה בין חבילות חיווט ספציפיות של היצרן הראשי למשאיות כבדות לבין פתרונות חיווט של אופציונט או מותאמים אישית. חבילות חיווט של היצרן הראשי מתאימות בדרך כלל לסובלנות המפעלית ולשילוב במערכות, בעוד שחבילות חיווט מותאמות אישית יכולות להתחשב בצרכים של שדרוג או להוסיף תכונות כגון תאורה עזרית או טלמטיקה. הבחירה הנכונה תלויה בפלטפורמה של הרכב, בתפקוד הרצוי ובשקולות לטווח הארוך.

עיצובים מודולריים ותכנון להמשך זמן

איך חבילת חיווט יכולה להישאר רלוונטית עם התקדמות הטכנולוגיה? ארכיטקטורות מודולריות של חבילות חיווט למשאיות כבדות מאפשרות הוספה או החלפה של מקטעים מבלי לבצע מחדש את כל רשת החיווט. הגישה הזו, שמביטה קדימה, מקטינה את עלות השדרוג ופועלת על שילוב של חיישנים חדשים, יחידות טלמטיקה או אביזרים צורכי כוח שעשויים להיתקן במהלך מחזור החיים של המשאית.

משקל, עלות ופערים ביעילות

איזון בחירת החומרים מול הביצועים

כל גרם נחשב בתעבורה כבדה כשמתחשבים במשקל הכולל של המטען ובצריכת הדלק.loomת הכבידה של המונית הכבדה חייבת לאזן בין גודל המוליך לצורך ביצוע אמין לבין הדרישה למזער את המשקל. מוליכים קלים יותר מקטינים את המסה אך עלולים לגרום לירידת מתח תחת עומסים כבדים. המעצבים ממקמים את המוליך, סוג הדיאלקטרית ונתיבי הloomת כדי לעמוד בדרישות הביצועים תוך שמירה על עלות ומשקל.

עלות בעלות וערך מחזור החיים

ההוצאה הראשונית היא רק חלק מהמשוואה. חבילת חיווט חזקה מפחיתה את תדירות התיקונים, מונעת הפסקות בשירות, ומקטינה את עלות הבעלות הכוללת. השקעה ראשונית מינימלית יותר ברכיבי חבילת חיווט איכותיים ובהגנות הנוספות, לרוב משתלמת על ידי פחות תיקונים, פחות תמיכה בדרכים, ושיפור זמני פעולה עבור פעולות מסחריות.

בטיחות וامتثال לתקנות

הענות לסטנדרטים ואישורים

מערכות חשמל של משאיות כבדות חייבות לעמוד בתקנות של תקינות כביש, תאימות אלקטרומגנטית ובטיחות.arness חשמלי של משאית כבדה תואם ייבדק ביחס לביצועי EMI/EMC, דירוגי דלקתיות ותאימות להגנה מפני חדירת מים. עמידה בתקנים אלו מגינה על ציי רכב מאיומים רגולטוריים ומעמיקה את הביטחון בתפעול בטוח.

השלכות על ביטחון הנהג ומשאיות כבדות

תקלות חשמליות עשויות ליצור מצבים מסוכנים - החל מאיבוד פתע של תאורה וכלה בהפסקת מנוע בפקקים. על ידי ודואים כי ה-arness חשמלי של המשאית הכבדה מותאם ומשומר כראוי, ציי רכב מגינים על הנהגים ועל שאר משתמשי הכביש. בדיקות שגרתיות של נתיבי הארנס, החיבורים ונקודות ההתקנה מהווים רכיב חיוני בתכניות הביטחון המונעות.

חדשנות וטכנולוגיות עולות

ארנסים חכמים ואבחון טעון

העתיד מצביע על חגורות שיכולות לעשות יותר מלהעביר כוח ואותות - הן יכולות לפקח על מצבן. רעיונות של חגורות למשאיות כבדות חכמות כוללים חיישנים משובצים וקווי אבחון שמדווחים על טמפרטורה, רעידות ועל שלמות החיבור. זיהוי מוקדם של ירידה באיכות מאפשר תחזוקה מוקדמת ומונע כשלים יקרים.

שימוש בחומרים מתקדמים ובלכסון

Сплавים חדשים למוליכים, לכסון משופר, ובידוד קל משקל וمقاומת למד lửa משפרים את ביצועי החגורה. התקדמות זו עוזרת למשאיות כבדות לפעול באופן מהימן עם מערכות אלקטרוניות צפופות יותר, תוך שמירה על עמידות בפני מתח סביבתי. התוצאה היא חגורה למשאית כבדה שתומכת באלקטרוניקה מודרנית מבלי להקריב את היציבות.

אסטרטגיית תחזוקה לשימור

בדיקות מתוכננות ושיקום מונע

בדיקה רגילה של מקלטים, תופסים וחטכים חשופים של הארנס של משאית כבדה תופסת בלאי לפני שגיאות מתרחשות. ניקוי של מקלטים המורגלים לקורוזיה, הוספת שמן דיאלקטרי כאשר זה רלוונטי, ו תיקון בידוד שנפגע הם התערבויות קטנות שמאריכות את חיי הארנס ופוחתות את הצורך בתיקונים דחופים.

אימון טכנאים על פרקטיקות מומלצות לשימוש בארנס

הכשרת צוות תחזוקה עם כישורים ספציפיים לארנס מביאה לתועלות מדידות. טכניקות מתאימות להגדרת מקלטים, הבנה של עדיפויות בנתיבי הארנס, ו פרקטיקות בטוחות לחיבור וחיברור שימרו על שלמות המערכת. טכנאים בעלי ידע מקטין את הסיכון לתיקונים לא תקינים שעלולים לפגוע בשיפורים בביצועים שארנס מותאם לספק.

טיפים ליישום עבור מנהלי צי

ลำד circuits קריטיים

לא כל המעגלים שווים. מנהלי ציוד צריכים לזהות מעגלים קריטיים - למשל, בקרת המנוע, חיישנים לבלמים ואורות - ולדאוג שיקבלו את הגנה מקסימלית על הרכות. חיזוק הנתיבים הללו מקטין את הסיכון למערכות קריטיות לבטחה ותומך בפעילות ללא הפסקות.

תכנון מחזור חיים ודרכי שדרוג

תכנון מראש להעצרת, הרחבת טלקומוניקציה או מערכות עזר מפשט את תהליכי שדרוג הרכות. כשעיצוב הרכות של המונית הכבדה המקורית תואמת את הצמיחה האפשרית, נמוכות ההוצאות על שדרוג חוזר ומתרחב האינטגרציה, מה שמגביר חיסכון בזמן ובכסף בטווח הקצר והארוך.

שאלות נפוצות

מה בדיוק עושה רכות מונית כבדה ברכב מודרני?

רכות מונית כבדה מנהלת את זרם החשמל ואת אותות התקשורת בין רכיבי המפתח במונית - בקרים של מנוע, חיישנים, אורות, מערכות בלמים ואלקטרוניקה של הקבינה - ומבטיחה תפעול מהימן ומגינה על המעגלים מפני נזקי סביבה.

באיזו תדירות יש לבדוק את הארנשת של משאית כבדה?

רווחי הבדיקה תלויים בתנאי הפעולה, אך בדיקה שוטפת במהלך תחזוקה מתוכננת, לפחות אחת למספר חודשים עבור צי מנועים עם נסיעה רבה, עוזרת לזהות בלאי, קורוזיה או שחיקה לפני שהן גורמות לתקלות.

האם ארנשת משאית כבדה פגומה יכולה לגרום לבעיות בתפקוד המנוע?

כן. חיווט פגום, חיבורים לקויים או התנגדות גבוהה בארנשת משאית כבדה יכולים לפגוע במדידות חיישנים ובתפקוד האקטואטורים, מה שגורם להתנהגות לא יציבה של המנוע, ירידה ביעילות הדלק וקודים לא צפויים של תקלות.

האם עדיף לתקן או להחליף ארנשת משאית כבדה שפגה?

ההחלטה תלויה בדרגת הנזק. תיקונים מקומיים יכולים להיות יעילים עבור שחיקה קלה או חיבור פגום, אך כשלון בolated החשמל, קורוזיה או תקלות חוזרות מוצדקות לרוב החלפה מלאה של הארנשת כדי לשחזר את האמינות ולקטין את עלויות התחזוקה לטווח הארוך.