Maximizing Fleet Efficiency Through Advanced Wiring Solutions

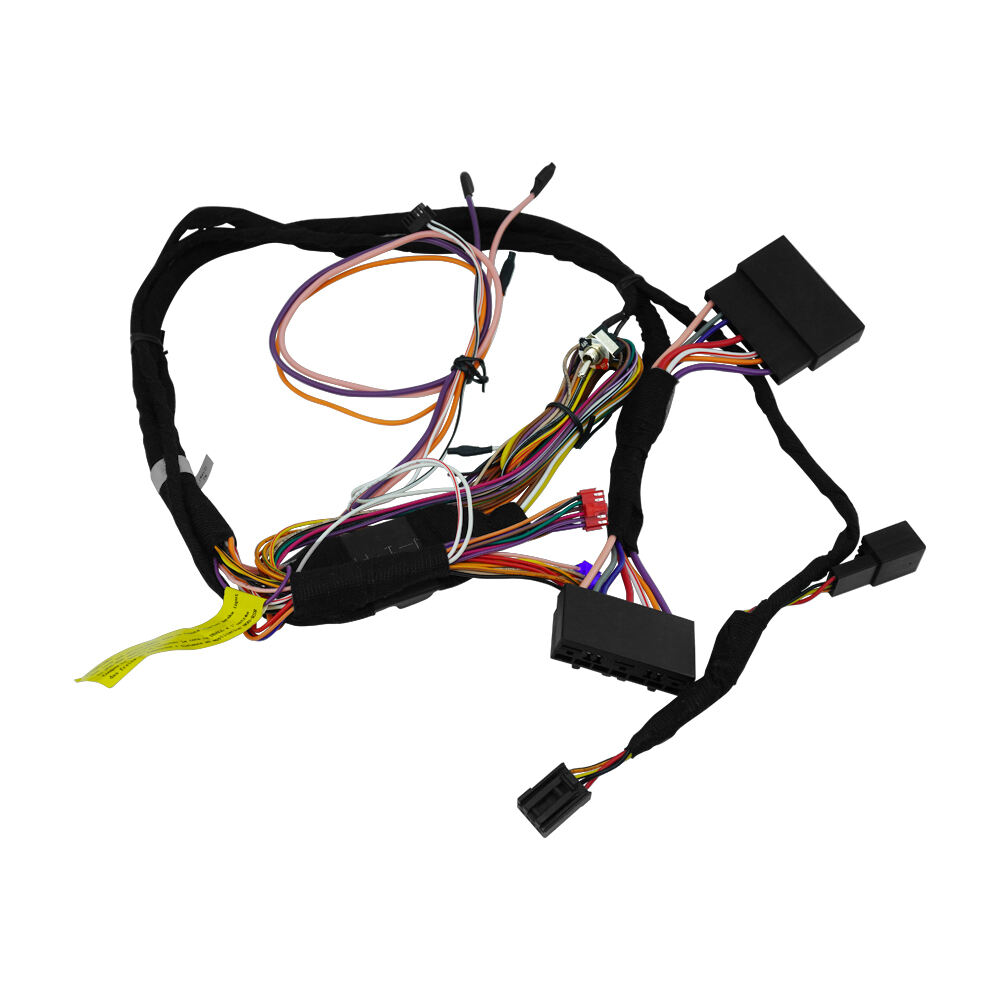

The heavy truck harness serves as the central nervous system of modern commercial vehicles, orchestrating crucial electrical connections that power everything from essential safety features to advanced performance monitoring systems. In today's competitive transportation industry, the quality and efficiency of your fleet's electrical harness system can make the difference between optimal performance and costly downtime.

Modern heavy truck harness systems have evolved significantly, incorporating sophisticated technologies that enhance vehicle reliability, safety, and overall operational efficiency. This comprehensive guide explores the various ways these essential components contribute to improved productivity and bottom-line results for fleet operators.

Core Components and System Integration

Advanced Connectivity Solutions

The heavy truck harness integrates multiple subsystems through a complex network of wires, connectors, and modules. These components work in harmony to ensure seamless communication between various vehicle systems, from engine management to cabin controls. High-quality harness systems utilize military-grade connectors and shielded cables to maintain signal integrity even in harsh operating conditions.

Modern harness designs incorporate redundant circuits and fail-safe mechanisms that prevent total system failures. This sophisticated approach to system architecture ensures that even if one component experiences issues, critical vehicle functions remain operational, minimizing unexpected downtime.

Diagnostic Integration Capabilities

Today's heavy truck harness systems feature built-in diagnostic capabilities that enable real-time monitoring and troubleshooting. Advanced sensors integrated throughout the harness network continuously collect data about system performance, voltage levels, and potential issues. This proactive approach to maintenance helps fleet managers identify and address potential problems before they lead to costly breakdowns.

The diagnostic features within modern harness systems also facilitate easier maintenance procedures, as technicians can quickly pinpoint exact locations of electrical issues using specialized diagnostic tools that interface with the harness network.

Performance Enhancement Features

Power Distribution Optimization

A well-designed heavy truck harness optimizes power distribution throughout the vehicle, ensuring each component receives the precise voltage and current required for optimal performance. This careful power management reduces strain on the electrical system, extends component life, and improves fuel efficiency by minimizing unnecessary power consumption.

Advanced power distribution modules within the harness system also provide intelligent load shedding capabilities, automatically prioritizing critical systems during high-demand situations to prevent system overload and potential damage.

Environmental Adaptability

Modern heavy truck harness systems are engineered to withstand extreme environmental conditions while maintaining optimal performance. High-quality materials and protective coatings guard against temperature variations, moisture, chemicals, and physical stress. This environmental resilience ensures consistent operation across diverse climate zones and operating conditions.

The robust design of contemporary harness systems includes specialized routing and securing methods that protect against vibration damage, a common cause of electrical system failures in commercial vehicles.

Safety and Compliance Benefits

Enhanced Safety Features

The heavy truck harness plays a crucial role in supporting advanced safety systems, including electronic stability control, collision avoidance, and brake management systems. Modern harness designs ensure reliable communication between these safety-critical components, contributing to improved vehicle control and accident prevention.

Integrated circuit protection features within the harness system help prevent electrical fires and component damage, while sophisticated grounding systems minimize the risk of electrical hazards during maintenance and operation.

Regulatory Compliance Integration

Contemporary heavy truck harness systems are designed to meet or exceed all relevant safety and emissions regulations. The integrated architecture supports seamless implementation of mandatory safety features and emissions control systems, ensuring fleets remain compliant with evolving industry standards.

Advanced monitoring capabilities built into the harness system help fleet operators maintain detailed records of safety system performance and emissions control effectiveness, simplifying compliance reporting and certification requirements.

Operational Cost Reduction

Maintenance Efficiency

Modern heavy truck harness designs incorporate modular components and standardized connectors that significantly reduce maintenance time and costs. Quick-disconnect features and clearly labeled circuits enable faster repairs and reduce the potential for errors during service procedures.

The integration of smart diagnostics and preventive maintenance alerts helps fleet operators optimize maintenance schedules, reducing unnecessary service intervals while preventing costly emergency repairs.

Fuel Economy Impact

The efficient power management capabilities of advanced harness systems contribute to improved fuel economy through optimized electrical load distribution and reduced parasitic power losses. Smart power management features automatically adjust system operation to minimize unnecessary energy consumption during different driving conditions.

Integration with engine management systems through the heavy truck harness enables more precise control of fuel injection and combustion parameters, leading to improved efficiency and reduced fuel consumption.

Future-Ready Technology Integration

Scalability and Upgrades

Modern heavy truck harness systems are designed with future expansion in mind, featuring additional capacity and pre-wired connections for upcoming technology implementations. This forward-thinking approach reduces the cost and complexity of adding new features or upgrading existing systems.

The modular nature of contemporary harness designs allows for easy integration of emerging technologies such as advanced driver assistance systems (ADAS) and connected vehicle capabilities without requiring complete system replacement.

Telematics Compatibility

The heavy truck harness serves as the foundation for advanced telematics systems, enabling real-time data collection and transmission for fleet management purposes. Built-in communication protocols support integration with various telematics platforms, providing valuable insights into vehicle performance and driver behavior.

Advanced data collection capabilities facilitated by the harness system enable predictive maintenance strategies and optimization of route planning, further enhancing operational efficiency.

Frequently Asked Questions

How often should a heavy truck harness be inspected?

Professional inspection of the heavy truck harness should be conducted during regular maintenance intervals, typically every 25,000 miles or as recommended by the manufacturer. However, visual checks for obvious damage or wear should be performed during daily vehicle inspections.

What are the signs of a failing truck harness system?

Common indicators include intermittent electrical issues, flickering lights, unexpected warning lights on the dashboard, or problems with multiple electrical systems simultaneously. Any burning smell or visible damage to wiring should be addressed immediately by a qualified technician.

Can a heavy truck harness be upgraded to support new technologies?

Yes, modern harness systems are designed with modularity in mind, allowing for the addition of new components and technologies. However, the specific upgrade capabilities depend on the original harness design and the requirements of the new technology being added.

What maintenance practices help extend harness life?

Regular inspection of connections, proper securing of loose wires, keeping drainage holes clear, and promptly addressing any signs of wear or corrosion can significantly extend the life of a heavy truck harness. Additionally, using proper cleaning products and avoiding high-pressure washing of electrical components helps prevent damage.