Understanding How a Wiring Harness Simplifies Complex Electrical Systems

In today's technological age, electrical systems in various devices, especially vehicles and industrial machinery, have become increasingly intricate. As electronics evolve, the need for efficient and reliable power distribution and signal transmission has grown. This is where the importance of a wiring harness becomes evident. A wiring harness simplifies complex electrical systems by neatly organizing wires, ensuring efficient power flow, and preventing failures due to tangled or exposed wires.

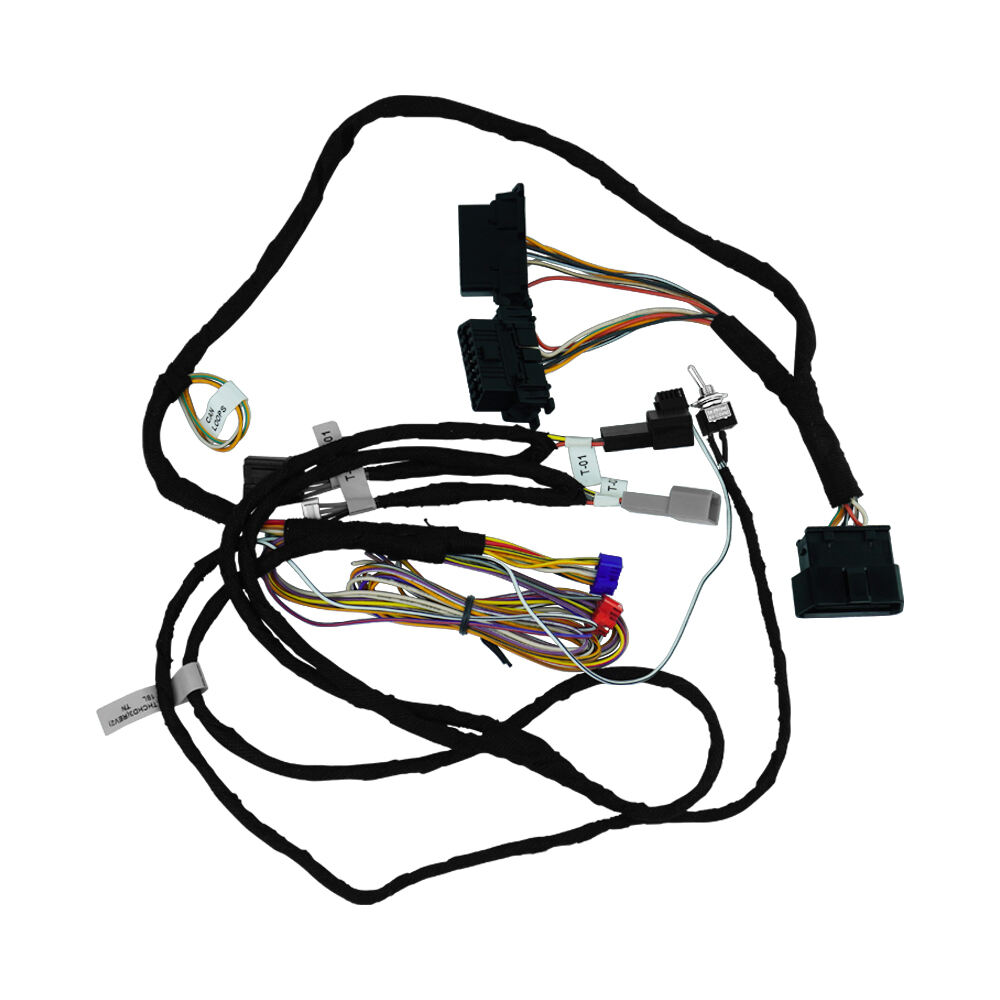

A wiring harness is a carefully designed bundle of wires, connectors, and insulation that connects different electrical components in a system. By consolidating multiple wires into a single unit, a wiring harness reduces clutter, increases safety, and improves performance. In this article, we will explore how wiring harnesses help simplify electrical systems and their impact on efficiency, safety, and ease of maintenance.

The Function of a Wiring Harness

Efficient Organization of Electrical Wires

One of the primary functions of a wiring harness is to organize multiple wires into a cohesive, manageable system. In modern electrical systems, such as those found in automobiles, electronics, and machinery, numerous wires are required to carry power and signals to various components. Without a wiring harness, these individual wires would be difficult to manage, leading to chaos and inefficiency.

By grouping the wires together, a wiring harness reduces the risk of tangling and confusion, ensuring that each wire serves its purpose without interference. This is especially important in complex systems, where multiple connections need to be made between different parts. The streamlined design of a wiring harness allows manufacturers to maintain order in their electrical systems while improving the aesthetic and functionality of the product.

In addition, the harness helps to keep the wires insulated, ensuring that they do not come into contact with each other, potentially causing short circuits. This organized structure helps optimize the system’s performance by reducing the possibility of electrical failures and improving the reliability of the entire system.

Simplifying Installation and Maintenance

When it comes to the assembly or repair of complex electrical systems, a wiring harness significantly simplifies the process. By using a single unit that connects various components, installers can quickly and easily connect electrical parts without having to deal with individual wires. This simplifies the overall assembly process, reducing labor time and improving productivity.

Wiring harnesses also make it easier to troubleshoot electrical problems. If an issue arises, technicians can easily locate the wiring harness and inspect its components, as opposed to searching through a complex maze of individual wires. The modular design of a wiring harness helps streamline maintenance procedures, ensuring that repairs can be completed more efficiently, with minimal downtime.

Furthermore, when modifications or upgrades to an electrical system are necessary, wiring harnesses make it easy to incorporate new components or adjust existing ones. The flexibility of a wiring harness allows for straightforward adaptations, making it simpler to scale up or enhance electrical systems without a complete overhaul.

Benefits of Using a Wiring Harness

Increased Safety and Reduced Risk of Damage

Electrical safety is one of the most critical aspects of any electrical system, and a wiring harness plays a key role in ensuring that systems remain safe and functional. One of the risks associated with unorganized wiring is the potential for wires to become frayed, damaged, or exposed, leading to electrical fires, shorts, or other safety hazards. A properly designed wiring harness prevents these risks by providing insulation and protective coverings for each wire.

Additionally, wiring harnesses help prevent abrasion or physical damage to the wires. In environments where wires may be subjected to vibrations, heat, or external impacts, a wiring harness provides an extra layer of protection, ensuring that the wires remain intact and functional. This enhanced safety reduces the likelihood of malfunctions that could result in costly repairs or, more importantly, pose a danger to users or operators.

For automotive applications, the safety benefits are particularly significant. Modern vehicles have complex electrical systems that control everything from airbag deployment to braking systems. A faulty wire can result in malfunctioning safety systems, putting lives at risk. A wiring harness ensures that each system is properly connected and protected, minimizing the risk of dangerous electrical failures.

Enhanced Efficiency and Performance

In complex electrical systems, ensuring that the power is distributed efficiently is vital. Wiring harnesses contribute to this by providing a direct and clear path for electrical signals to travel from one component to another. By reducing the complexity of wiring layouts, the harness ensures that the system works more efficiently, reducing energy loss and improving overall performance.

For example, in automotive applications, a wiring harness helps ensure that power from the battery is distributed properly to various electrical systems, such as the lights, engine control unit (ECU), and infotainment system. With a well-organized harness, these components receive the power they need without unnecessary resistance or power loss. The result is better fuel efficiency and improved overall vehicle performance.

Wiring harnesses also help with the proper grounding of electrical components, which is essential for efficient operation. In systems like industrial machinery, a grounded wiring harness ensures that electrical signals are transmitted without interference, improving the accuracy and reliability of the system.

Wiring Harness Design and Customization

Tailored for Specific Applications

One of the advantages of using wiring harnesses in complex electrical systems is the ability to customize the harness for specific applications. While standard wiring harnesses can be used in many systems, custom-designed harnesses allow manufacturers to tailor the system to meet the unique requirements of a particular product.

For example, automotive manufacturers may need custom wiring harnesses for different vehicle models, depending on the number of electrical components and the space available within the vehicle. Similarly, industrial machinery may require specialized wiring harnesses that can withstand high temperatures, vibrations, or exposure to chemicals. Custom wiring harnesses ensure that each system is optimized for performance, safety, and durability.

By designing a harness specifically for a given application, manufacturers can reduce the complexity of the wiring, streamline installation, and ensure that the system functions as intended. This level of customization is especially important in industries like aerospace, automotive, and robotics, where the precise functioning of electrical systems is critical to performance and safety.

Optimizing for Space and Weight

Space and weight considerations are essential when designing electrical systems, especially in vehicles, aerospace applications, and consumer electronics. A wiring harness helps to optimize the use of space by consolidating the wiring into a single unit, reducing the clutter associated with individual wires.

By streamlining the electrical layout, manufacturers can use space more effectively, allowing for better organization and providing room for other important components. This is particularly beneficial in industries where space is limited, such as in automotive engineering, where vehicle design must account for comfort, safety, and aerodynamics.

Similarly, a wiring harness helps reduce the overall weight of the system, which is crucial for applications like automotive design and aviation. By minimizing the number of wires and connectors, manufacturers can reduce the total weight, contributing to better fuel efficiency, improved handling, and enhanced performance.

FAQ

How does a wiring harness improve safety?

A wiring harness reduces the risk of electrical malfunctions, short circuits, and fires by keeping wires properly insulated and organized. This helps prevent damage to the wires and ensures that the vehicle or equipment remains safe during operation.

Why is customization important for a wiring harness?

Customization allows the wiring harness to be tailored to the specific needs of the electrical system. This ensures optimal performance, reduced complexity, and the ability to meet unique requirements, such as space constraints, environmental factors, and safety standards.

How does a wiring harness impact system efficiency?

By organizing wires and optimizing power distribution, a wiring harness ensures that electrical signals flow efficiently through the system. This reduces energy loss, improves performance, and minimizes the risk of malfunctions.

Can a wiring harness help with maintenance?

Yes, wiring harnesses simplify maintenance by providing easy access to the electrical system, making it easier to identify and repair issues. This modular design also helps reduce downtime and repair costs, as the harness allows for quick troubleshooting.